OEM/ODM Manufacturer China Suspension Arm Rubber Bushing for Toyota Yr21 (48706-28010)

Being supported by an advanced and expert IT crew, we could give technical support on pre-sales & after-sales assistance for OEM/ODM Manufacturer China Suspension Arm Rubber Bushing for Toyota Yr21 (48706-28010), We play a leading role in providing customers with high quality products good service and competitive prices.

Being supported by an advanced and expert IT crew, we could give technical support on pre-sales & after-sales assistance for China Suspension Arm Bushing, Control Arm Bushing, With its rich manufacturing experience, high-quality products and solutions, and perfect after-sale service, the company has gained good reputation and has become one of the famous enterprise specialized in manufacturing series.We sincerely hope to establish business relation with you and pursue mutual benefit.

Details

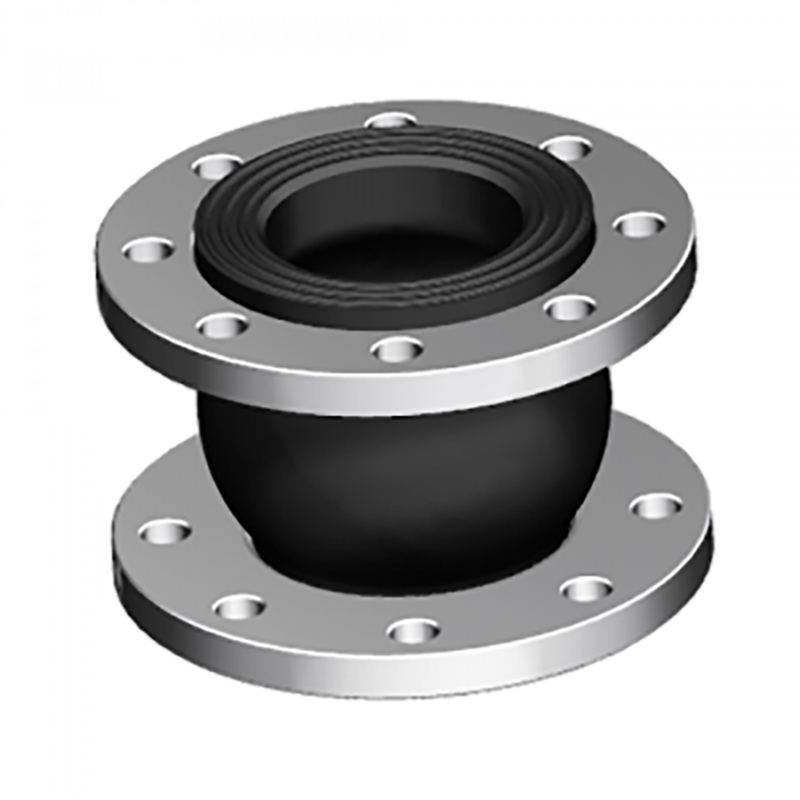

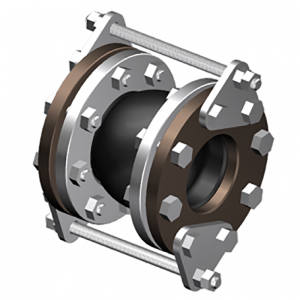

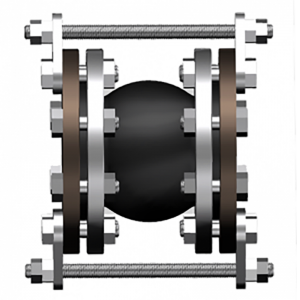

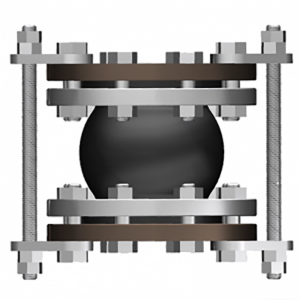

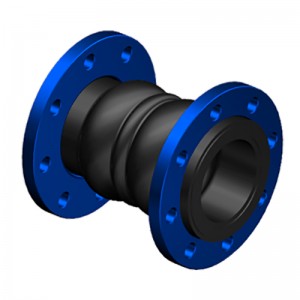

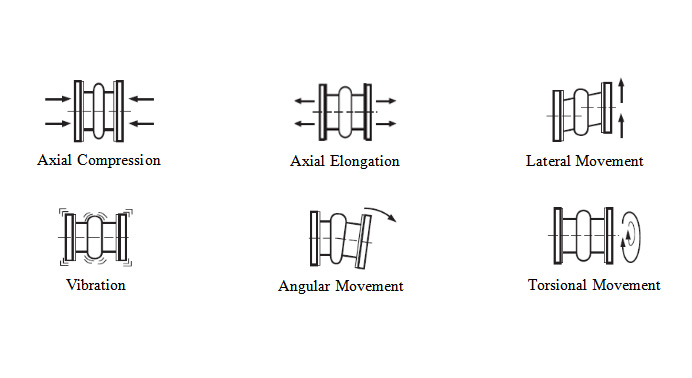

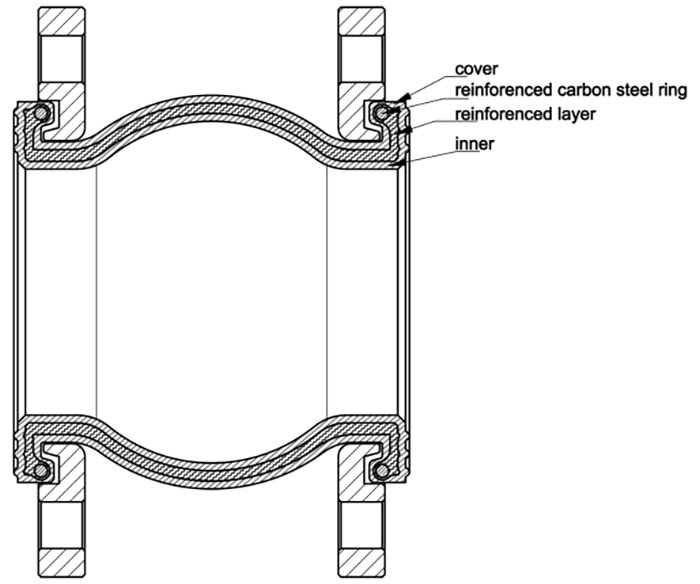

The single-arch product can reduce the vibration and noise, which can also solve the axial/lateral/angular movements/eccentric problems. Reinforcement layer of the bellows by Nylon cords and at both ends by hardened steel wire rings. The floating steel flanges are drilled according to DIN, ANSI, BS, JIS and other standards. If the piping pressure is much higher, reinforced bolts should be assembled together with flanges.

| Specifications | I | II | III |

| Working Pressure Mpa (Kgf/Cm2) | 1Mpa (10) | 1.6 (16) | 2.5 (25) |

| Test Pressure | 1.5Mpa | 2.4Mpa | 3.75Mpa |

| Burst Pressure Mpa (Kgf/Cm2) | 3 (30) | 4.8 (48) | 5.5 (55) |

| Vacuum Kpa (Kgf/Cm2) | 53 (400) | 86(660) | 100 (750) |

| Materials | EPDM/NBR/SBR/NR | ||

| Diameter Range | DN15-DN600 (1/2″-24″) | ||

| Connection Method | FLANGETHREADCLAMP | ||

| Flanges Dimensions | DIN, EN,ANSI, BS, JIS and other standards | ||

| Applicable Medium | Air, compressed air, water, seawater, hot water, oil, acid, alkali etc. | ||

| Loading Port: | Qingdao, China | ||

| Shipment Terms: | FOB, CFR, CIF | ||

| Production Capacity: | 50000 set | ||

| Payment Terms: | L/C, T/T, D/P | ||

| Connection: | Flange, Thread | ||

| Flange Material: | Carbon Steel, Stainless Steel | ||

| Period of Delivery | about 21 working days | ||

|

Single Arch-Standard Length |

||||||||

|

Dimensions |

Movement Distance |

Operating Condition |

||||||

|

Pipe Size |

Standard O’all Length |

Axial Compression |

Axial Extension |

Lateral Deflection |

Angular Deflection |

Max w.p. bar(psi) |

Max Vacuum (mm hg) / Kmpa |

|

|

Inch |

mm |

mm |

mm |

mm |

mm |

|||

|

1 1/4″ |

32 |

95 |

10 |

6 |

10 |

25° |

16(225) |

700(86Kpa) |

|

1 1/2″ |

40 |

95 |

10 |

6 |

10 |

25° |

16(225) |

700(86Kpa) |

|

2″ |

50 |

105 |

10 |

6 |

10 |

25° |

16(225) |

700(86Kpa) |

|

2 1/2″ |

65 |

115 |

15 |

8 |

12 |

25° |

16(225) |

700(86Kpa) |

|

3″ |

80 |

135 |

15 |

8 |

12 |

25° |

16(225) |

700(86Kpa) |

|

4″ |

100 |

135 |

20 |

12 |

16 |

15° |

16(225) |

700(86Kpa) |

|

5″ |

125 |

165 |

20 |

12 |

16 |

15° |

16(225) |

700(86Kpa) |

|

6″ |

150 |

180 |

20 |

12 |

16 |

15° |

16(225) |

700(86Kpa) |

|

8″ |

200 |

205 |

20 |

12 |

16 |

15° |

16(225) |

700(86Kpa) |

|

10″ |

250 |

240 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

12″ |

300 |

260 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

14″ |

350 |

265 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

16″ |

400 |

265 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

18″ |

450 |

265 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

20″ |

500 |

265 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

24″ |

600 |

265 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

Single Arch-130MM |

||||||||

|

Dimensions |

Movement Distance |

Operating Condition |

||||||

|

Pipe Size |

Special O’all Length |

Axial Compression |

Axial Extension |

Lateral Deflection |

Angular Deflection |

Max w.p. bar(psi) |

Max Vacuum (mm hg) / Kmpa |

|

|

Inch |

mm |

mm |

mm |

mm |

mm |

|||

|

1 1/4″ |

32 |

130 |

30 |

20 |

20 |

35° |

16(225) |

660(26) |

|

1 1/2″ |

40 |

130 |

30 |

20 |

20 |

35° |

16(225) |

660(26) |

|

2″ |

50 |

130 |

30 |

20 |

20 |

35° |

16(225) |

660(26) |

|

2 1/2″ |

65 |

130 |

30 |

20 |

20 |

30° |

16(225) |

660(26) |

|

3″ |

80 |

130 |

30 |

20 |

20 |

30° |

16(225) |

660(26) |

|

4″ |

100 |

130 |

30 |

20 |

20 |

25° |

16(225) |

660(26) |

|

5″ |

125 |

130 |

30 |

20 |

20 |

25° |

16(225) |

660(26) |

|

6″ |

150 |

130 |

30 |

20 |

20 |

15° |

16(225) |

660(26) |

|

8″ |

200 |

130 |

30 |

20 |

20 |

15° |

16(225) |

660(26) |

|

10″ |

250 |

130 |

30 |

20 |

20 |

10° |

16(225) |

660(26) |

|

12″ |

300 |

130 |

30 |

20 |

20 |

10° |

16(225) |

660(26) |

|

Single Arch-American Standard |

||||||||

|

Dimensions |

Movement Distance |

Operating Condition |

||||||

|

Pipe Size |

Special O’all Length |

Axial Compression |

Axial Extension |

Lateral Deflection |

Angular Deflection |

Max w.p. (psi)-3,-4 |

Max Vacuum (in. of Hg)-5 |

|

|

Inch |

mm |

inch |

inch |

inch |

inch |

|||

|

1″ |

25 |

6″ |

1/2″ |

3/8″ |

±1/2″ |

37° |

225 |

26 |

|

1 1/4″ |

32 |

6″ |

1/2″ |

3/8″ |

±1/2″ |

31° |

225 |

26 |

|

1 1/2″ |

40 |

6″ |

1/2″ |

3/8″ |

±1/2″ |

27° |

225 |

26 |

|

2″ |

50 |

6″ |

1/2″ |

3/8″ |

±1/2″ |

20° |

225 |

26 |

|

2 1/2″ |

65 |

6″ |

1/2″ |

3/8″ |

±1/2″ |

17° |

225 |

26 |

|

3″ |

80 |

6″ |

1/2″ |

3/8″ |

±1/2″ |

14° |

225 |

26 |

|

4″ |

100 |

6″ |

3/4″ |

1/2″ |

±1/2″ |

14° |

225 |

26 |

|

5″ |

125 |

6″ |

3/4″ |

1/2″ |

±1/2″ |

11° |

225 |

26 |

|

6″ |

150 |

6″ |

3/4″ |

1/2″ |

±1/2″ |

9° |

225 |

26 |

|

8″ |

200 |

6″ |

3/4″ |

1/2″ |

±1/2″ |

7° |

225 |

26 |

|

10″ |

250 |

8″ |

1″ |

5/8″ |

±3/4″ |

7° |

225 |

26 |

|

12″ |

300 |

8″ |

1″ |

5/8″ |

±3/4″ |

6° |

225 |

26 |

|

14″ |

350 |

8″ |

1″ |

5/8″ |

±3/4″ |

5° |

150 |

26 |

|

16″ |

400 |

8″ |

1″ |

5/8″ |

±3/4″ |

4° |

150 |

26 |

|

18″ |

450 |

8″ |

1″ |

5/8″ |

±3/4″ |

4° |

150 |

26 |

|

20″ |

500 |

8″ |

1″ |

5/8″ |

±3/4″ |

3° |

150 |

26 |

|

24″ |

600 |

10″ |

1″ |

5/8″ |

±3/4″ |

3° |

150 |

26 |

|

Single Arch-Jis Standard |

||||||||

|

Dimensions |

Movement Distance |

Operating Condition |

||||||

|

Pipe Size |

Special O’all Length(mm) |

Axial Compression |

Axial Extension |

Lateral Deflection |

Angular Deflection |

Max w.p. bar(psi) |

Max Vacuum (mm hg) / Kmpa |

|

|

Inch |

mm |

inch |

inch |

inch |

inch |

|||

|

1 1/4 |

32 |

125 |

10 |

6 |

10 |

10° |

16(225) |

700(86Kpa) |

|

1 1/2 |

40 |

125 |

10 |

6 |

10 |

10° |

16(225) |

700(86Kpa) |

|

2 |

50 |

125 |

10 |

7 |

10 |

10° |

16(225) |

700(86Kpa) |

|

2 1/2 |

65 |

125 |

10 |

7 |

10 |

10° |

16(225) |

700(86Kpa) |

|

3 |

80 |

125 |

10 |

7 |

10 |

10° |

16(225) |

700(86Kpa) |

|

4 |

100 |

150 |

10 |

10 |

10 |

7° |

16(225) |

700(86Kpa) |

|

5 |

125 |

175 |

10 |

10 |

10 |

7° |

16(225) |

700(86Kpa) |

|

6 |

150 |

200 |

10 |

12 |

10 |

5° |

16(225) |

700(86Kpa) |

|

8 |

200 |

200 |

10 |

12 |

10 |

5° |

16(225) |

700(86Kpa) |

|

10 |

250 |

250 |

10 |

15 |

10 |

5° |

16(225) |

700(86Kpa) |

|

12 |

300 |

250 |

10 |

15 |

10 |

5° |

16(225) |

700(86Kpa) |

|

Single Arch-Domestic Market |

||||||||

|

Dimensions |

Movement Distance |

Operating Condition |

||||||

|

Pipe Size |

O’all Length |

Axial Compression |

Axial Extension |

Lateral Deflection |

Angular Deflection |

Max w.p. bar(psi) |

Max Vacuum (mm hg) / Kmpa |

|

|

Inch |

mm |

mm |

mm |

mm |

mm |

|||

|

1 1/4″ |

32 |

95 |

10 |

6 |

10 |

25° |

16(225) |

700(86Kpa) |

|

1 1/2″ |

40 |

95 |

10 |

6 |

10 |

25° |

16(225) |

700(86Kpa) |

|

2″ |

50 |

105 |

10 |

6 |

10 |

25° |

16(225) |

700(86Kpa) |

|

2 1/2″ |

65 |

115 |

15 |

8 |

12 |

25° |

16(225) |

700(86Kpa) |

|

3″ |

80 |

135 |

15 |

8 |

12 |

25° |

16(225) |

700(86Kpa) |

|

4″ |

100 |

150 |

20 |

12 |

16 |

15° |

16(225) |

700(86Kpa) |

|

5″ |

125 |

165 |

20 |

12 |

16 |

15° |

16(225) |

700(86Kpa) |

|

6″ |

150 |

180 |

20 |

12 |

16 |

15° |

16(225) |

700(86Kpa) |

|

8″ |

200 |

210 |

20 |

12 |

16 |

15° |

16(225) |

700(86Kpa) |

|

10″ |

250 |

230 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

12″ |

300 |

245 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

14″ |

350 |

255 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

16″ |

400 |

255 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

18″ |

450 |

255 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

20″ |

500 |

255 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

24″ |

600 |

260 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

Products categories

-

Phone

-

E-mail

-

Whatsapp

whatsapp

-

WeChat

Jessy Lin

-

WeChat

Ellen Zhang